U-turn wells are designed to mitigate the problem of production potential in really constrained leases or production units.

Lease spacing can restrict individual lateral lengths, reducing the rate potential of the well. By drilling two laterals, side-by-side and joined together, this problem can be mitigated. It’s not quite that simple though, as the turn means that the well must traverse a full 180° azimuth change, most likely crossing through the minimum and maximum horizontal stress directions. This means that understanding the geomechanical conditions in the wellbore becomes a key driver for operational success, amongst a suite of other interesting considerations for these types of wells.

Merlin, in partnership with H&J Petroleum, is at the forefront of U-turn drilling in the Delaware and Midland basins, having recently supported an operator who has just completed a world-record well of this type. Our partnership allows you to access highly experienced operations engineers and specialists, with a proven track record of success to support your projects through initial geomechanical design, U-turn drilling engineering feasibility and risk assessment and operations in the field – ensuring that lessons learned are applied on your location.

Engineering

Starting from a clean sheet of paper, Merlin can support the development of an engineered and de-risked U-turn well from the initial well design concept, through detailed geomechanical and drilling engineering feasibility. Merlin uses cutting-edge technology and hard-won industry expertise to create efficient, cost-effective solutions, enhancing the success and operational performance of these complex wells.

Operations

Merlin enables seamless execution of U-turn wells from the first build section to landing out the completion, offering real-time monitoring, troubleshooting, and process optimization. Merlin Advisors provide comprehensive assistance throughout the construction process supports maximum efficiency and minimum downtime for these complex wells.

Improve Drilling Speed

Navigate the complex geological formations of the Permian Basin more quickly and accurately, reducing the time needed to reach target depths.

Minimize NPT

Anticipate and mitigate potential issues before they escalate, reducing NPT (non-productive time) and maintaining consistent progress.

Reduce Drilling Risks

Minimize the risk of costly mistakes and equipment failures using Merlin’s knowledge of the local geology and best practices in drilling techniques.

Enhance Execution

Industry leading engineers provide better project planning and execution strategies, which can lead to more predictable and manageable project costs.

In Collaboration with H&J Petroleum

‘Merlin are world-class drilling engineering advisors, collaborators, and educators – specialising in delivery assurance for extended reach and complex wells. Established in 2007, Merlin has helped clients successfully deliver over 550 projects in 52 countries’.

‘H&J Petroleum build our teams based on shared principles and values. This means that when H&J partner with your company, you can rest assured that your project will be delivered on time, on budget, and within the expectations of your team culture’.

Merlin is excited to announce a new collaboration with H&J Petroleum, experts in Permian Basin drilling. By combining Merlin’s advanced engineering capabilities with H&J’s extensive regional expertise, Merlin offer unparalleled engineering and operations support.

Understanding U-turn Challenges

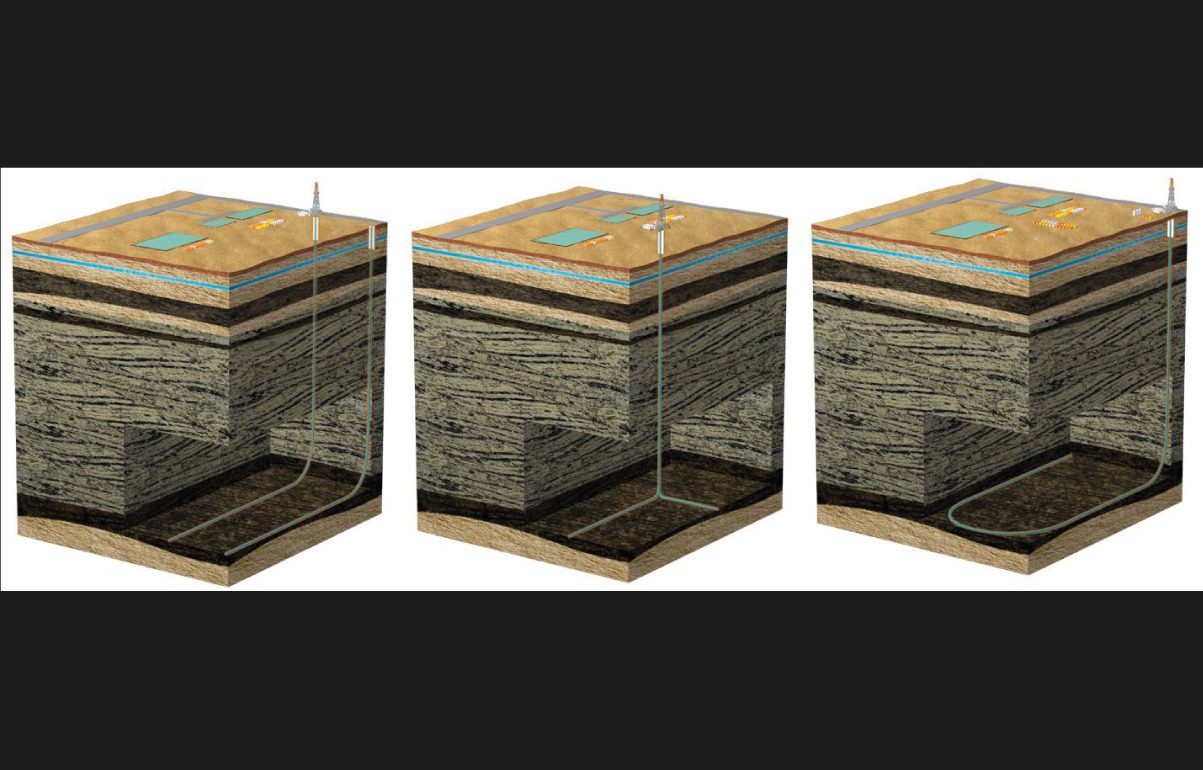

Drilling a U-turn well

A U-turn well is a type of directional drilling where the wellbore curves from a vertical to a horizontal trajectory, resembling a “U” shape. This design allows for greater contact with the reservoir in a small lease, compared to a conventional straight lateral. U-turn wells require a detailed understanding of the underlying geological conditions in order to be successful as the in-situ stress regime dictates mud weight, when then affects a suite of different engineering decisions and subsequent operational plans. Understanding drill string fatigue in the context of the directional plan is also important, as those variables become important in areas of high bending stress under load, which drives operational planning and quality control.

The complexity of drilling a U-turn well requires precise engineering and operational expertise to navigate geological challenges, maintain wellbore stability, and ultimately achieve maximum production potential. Merlin and H&J Petroleum have the combined experience to ensure project success.

Mastering U-turn Wells

Welcome to Merlin’s video presentation highlighting our specialized expertise in optimizing U-turn drilling projects. Through advanced engineering and meticulous operational support, we deliver tailored solutions to enhance efficiency and success in directional drilling. Discover how our experience can elevate your project’s performance in the challenging environments of the Permian Basin.