Friday Haggler

A reminder of last Friday’s Haggler

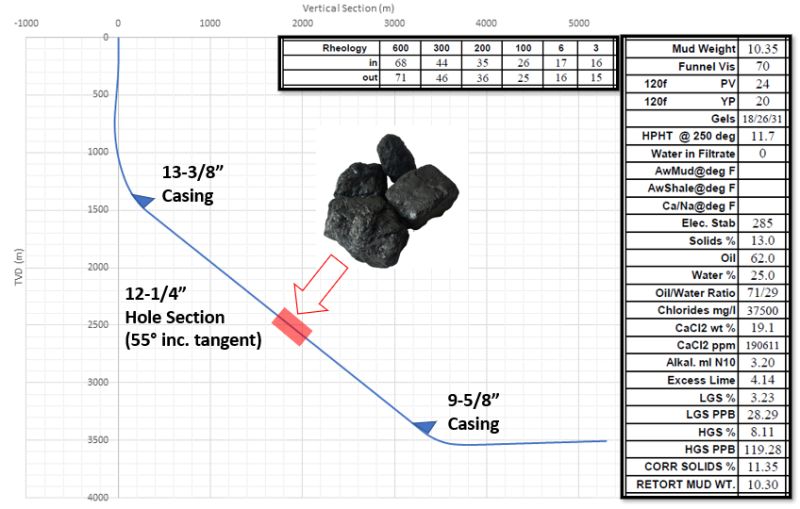

An offset well review shows previous wells have had problems in thick coal seams in the middle of the 12-1/4” hole section. The problems are caused by instability and losses in the coals and include pack-offs while reaming, tight hole when tripping on elevators and casing hanging up when running in hole. The coal seams cause most of the problems, however, the section has interbedded shales and sands, some of the shales require the 10.35ppg MW for stability and some of the sands are prone to losses if ECD is not controlled. Which of the following options are likely to help reduce risk in this section on the next well:

a) Under ream the hole section to reduce ECD.

b) Increase the gel strength to suspend the coal cavings/blocks in the low angle part of the well and to prevent them avalanching.

c) Increase the low-end rheology to improve hole cleaning in the enlarged coal interval.

d) Back-ream a full stand on connections while drilling the coal seams to condition the hole.

e) Retrofit a computer-controlled mud pump ramping system to the platform rig control system (it’s an old rig!).

f) Use larger bridging solids in the drilling fluid, with a range of sizes and some deformable material like graphite.

The Answer

Short Answer: e & f

No two coal seams are the same but the basic principal is to run the appropriate MW (see SPE-128728), minimise hydraulic and mechanical energy (low energy drilling practices) and rapidly bridge the fractures to minimise fluid invasion into the fracture cleats. See long answer below for more waffle.

Useful references: SPE-128728 (Steinar Ottesen) and SPE-125246 (Kilroy & Dupriest)

Long Answer: (a) No, the interval was described as interbedded, likely to produce high vibrations (bit and reamer in formation with differing strengths) and destabilise the coal by adding mechanical energy through lateral vibrations and whirl. Yes, it would reduce the ECD, but it’s not worth the destabilisation risk

(b) No, coal has a density of approx. 10.1ppg, it will therefore float without any gels

(c) No, the rheology is already on the high side (6RPM = 17) and we need to manage ECD. Enlargement is the problem not hole cleaning

(d) No, increased likelihood of mechanical damage to coal

(e) Yes, the gels are quite high, pressure spikes when brining pumps up is a high risk. Manual pumps are good for flexibility and breaking circulation can be done in a low-risk way with them, but a controlled system eliminates the reliance on the human being attached to the pump controls.

(f) Yes, larger solids are needed to plug the cleats in the coal, with deformable material / graphite plugging the gaps between the bridging solids. See references in the Short Answer comment for more detail.